Category

High Temperature Sic Heating Element, Sic Furnace Heater

SiC heating element is made from quality green SiC powder, which was also added some additives according to the material

Basic Info.

| Model NO. | SHIBO-SiC heating element |

| Structure Material | Non-Metallic Material |

| Principle | Resistance Heating |

| Heat Transfer Surface | Tubular Heat Exchanger |

| Condition | New |

| Size | Dia12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm |

| Product Name | High Temperature Sic Heating Element, Sic Furnace |

| Transport Package | Wooden Case |

| Specification | ISO9001 |

| Trademark | Shibo |

| Origin | China |

| HS Code | 85168000 |

| Production Capacity | 10ton/Month |

Product Description

SiC heating element is made from quality green SiC powder, which was also added some additives according to the materials proportion. SiC heating elements are non-metallic products, they have a series of characteristics, such as higher temperature, antioxidation, anticorrosion, increase temperature fast, low coefficient of thermal expansion and so on. Therefore, they are widely used in various kinds of furnace with temperature 800C to 1800C.Advantage of our SiC heating elements: stable quality, reasonable price, fast delivery

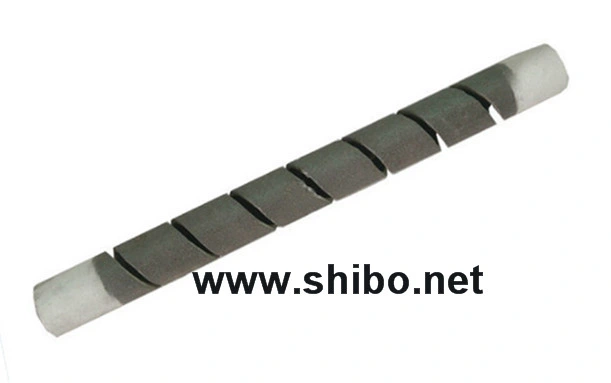

Types of SiC heating elements: dumbell type, rod type, U type, W type, H type, single spiral type, double spiral type

Sizes are available from Dia12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25 inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) for all types.

Specifications and resistance range

| diameter | Length of hot zone | Length of cold zone | Overall length | Resistance |

| 8 | 100-300 | 60-200 | 240-700 | 2.1-8.6 |

| 12 | 100-400 | 100-300 | 300-1100 | 0.8-5.8 |

| 14 | 100-500 | 150-350 | 400-1200 | 0.7-5.6 |

| 16 | 200--600 | 200-350 | 600-1300 | 0.7-4.4 |

| 18 | 200-800 | 200-400 | 600-1600 | 0.7-5.8 |

| 20 | 200-800 | 250-600 | 700-2000 | 0.6-6.0 |

| 25 | 200-1200 | 250-700 | 700-2600 | 0.4-5.0 |

| 30 | 300-2000 | 250-800 | 800-3600 | 0.4-4.0 |

| 35 | 400-2000 | 250-800 | 900-3600 | 0.5-3.6 |

| 40 | 500-2700 | 250-800 | 1000-4300 | 0.5-3.4 |

| 45 | 500-3000 | 250-750 | 1000-4500 | 0.3-3.0 |

| 50 | 600-2500 | 300-750 | 1200-4000 | 0.3-2.5 |

| 54 | 600-2500 | 300-250 | 1200-4000 | 0.3-3.0 |

Some data for furnace design of SiC heating elements

1.Distance of two heaters should be 1.5-4 times of diameter of cold zone.

2.The diameter of the hole on the wall should be 1.5times of the diameter of the heater.

Notes for using and installing the heater

1. Heater should be protected against damp during storing or installing to ensure the performance of the heater

2. In order to be sure of well-distributed load of each and groups heater should be divided before assembling. The tolerance of resistance of each one can not exceed by 10% each other.

3. Heater is hard and brittle, please be careful when assem bling and maintaining so as to avoid damage.

4. When operating the furnace at the beginning, the voltage should be increased slowly and can not be fully loaded at once. Otherwise the larger current will be resulted in the damage of heater

5. When heater is damaged and need to be changed, the resistance of new one should follow the increasing resistance. If many heaters are damaged or resistance increased too much, all heaters should be changed.

Application

SiC heating elements can be used in the furnace temperature 600C-1400C, directly in the air use as well, and it need not any protective atmosphere. Because of SiC heating elements well performance, they are widely used in high temperature furnace, ceramics, glass, analysis and test, semiconductor, science research.. etc

About us

1. Our company is a high & new technology enterprise specially engaged in developing, manufacturing and selling SiC (silicon carbide) heating elements.

2. It established in the year 2005, with more than 17 years experience for produciton.

3. Products are exported to USA, Germany, France, Poland, Spain,Turkey, Russia, Ukraine, Japan, Korea, Singapore, Vietnam, Thailand and Iran, etc.. They are highly approved by our customers all over the world.

4. Our eternal faith is "seeking for living with the quality, getting reputation with honesty, seeking for development with mutual benefit".